-

Car Seat Pressure Sensor

-

FSR Sensor - Force Sensing Resistor

-

Membrane Switch Sensor

-

Smart Seat Belt Reminder System

-

Smart Car 4G GPS DGT Luz V16 Light

-

Smart Baby Anti-abandonment Cushion

-

Smart Seat Occupancy Detection DIY Kit

-

Intelligent Asset Management System

-

Smart Refueling system

-

Smart Construction site

-

Smart Electric Vehicle anti-theft Monito

-

Smart Hospital Bed Occupancy and Fall Pr

-

Smart Hotel bed occupancy management

-

Smart Restaurant/Meeting room Seat Occup

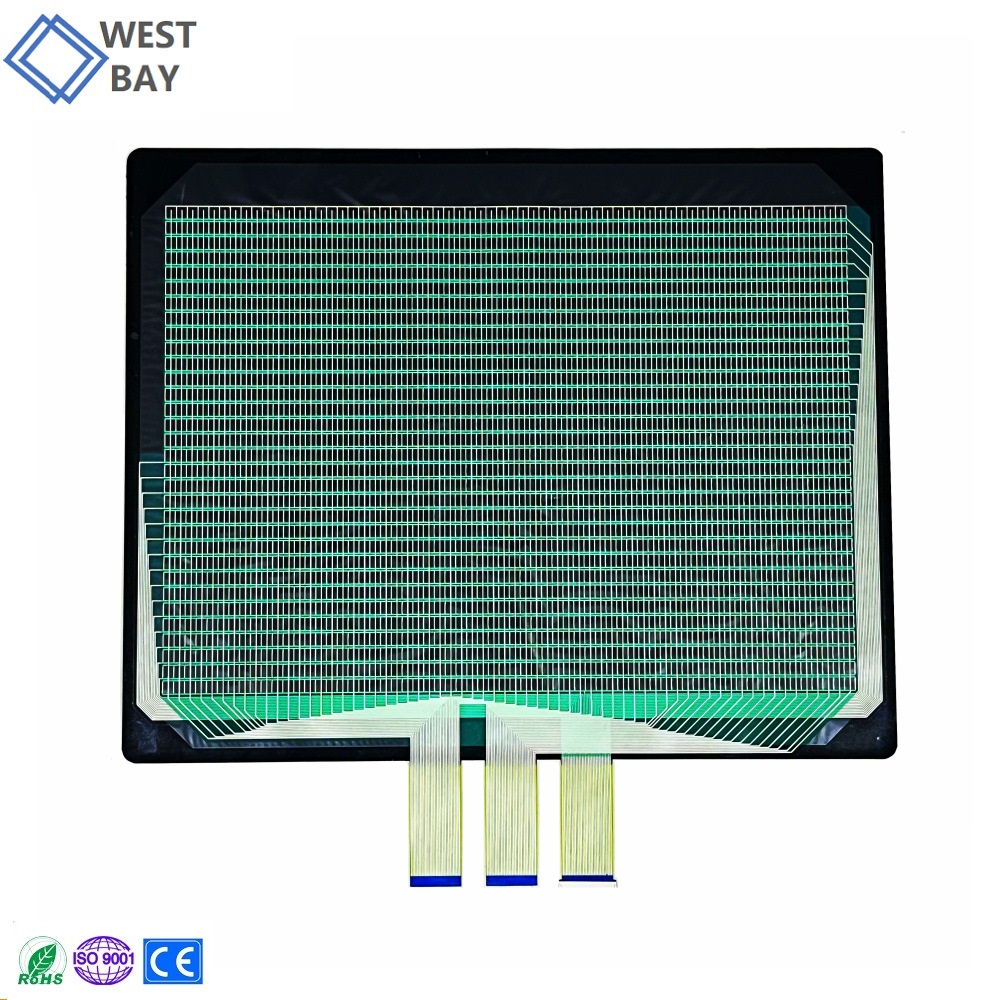

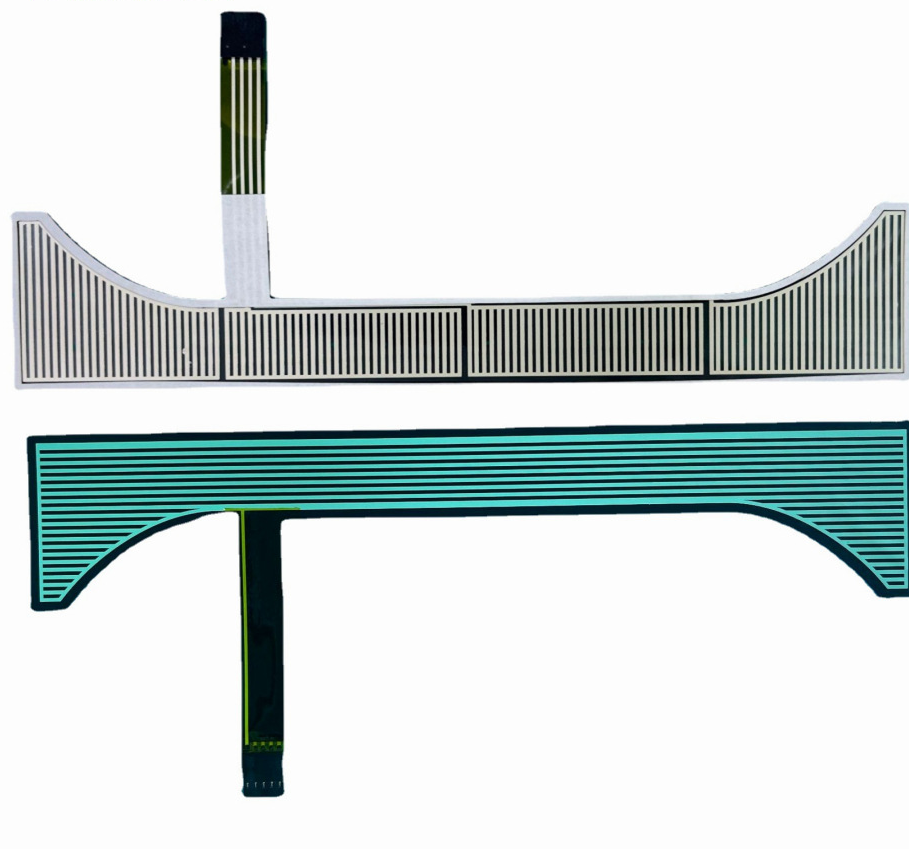

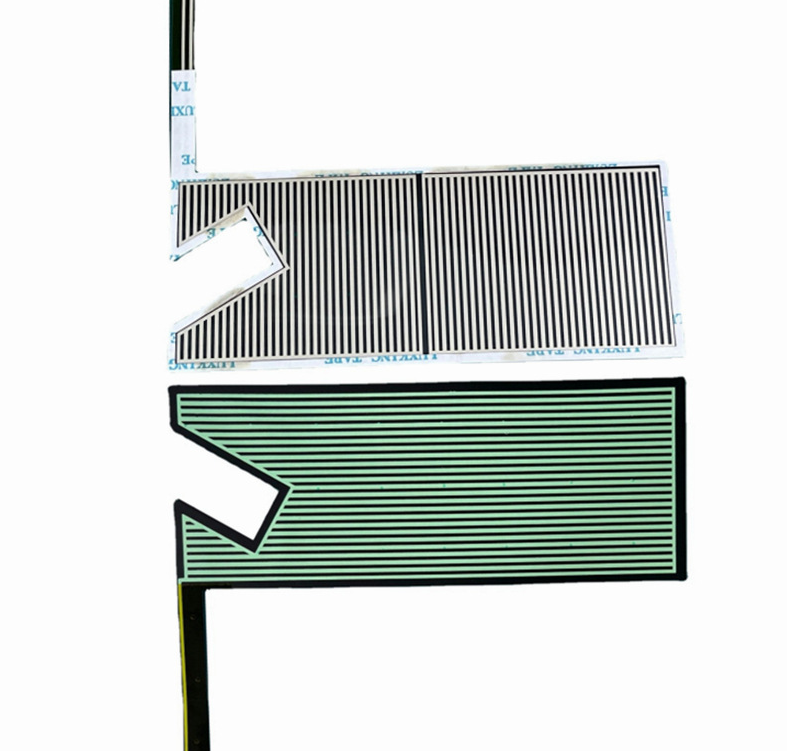

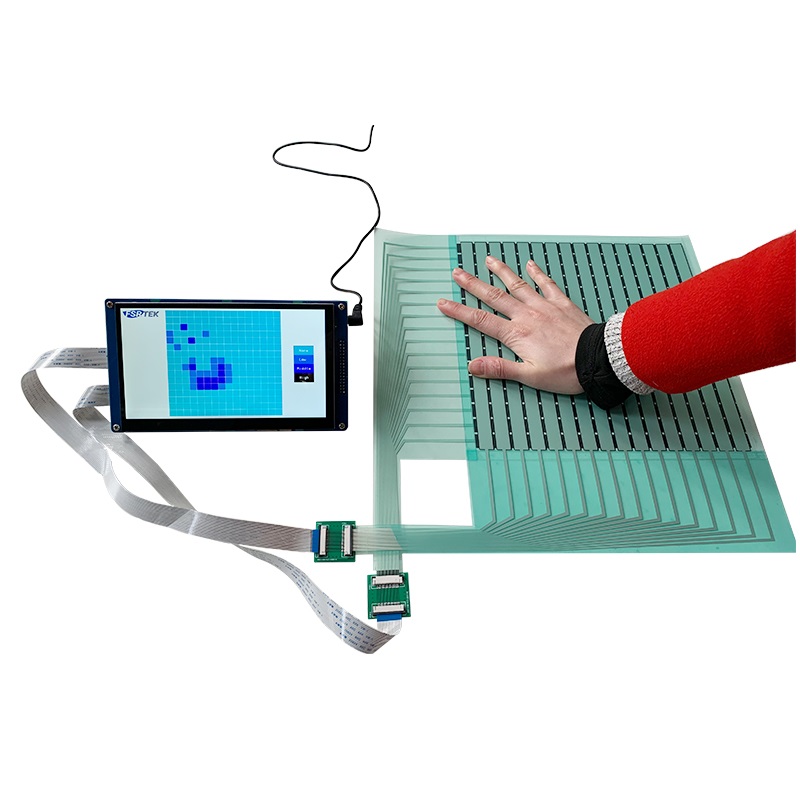

Westbay Customized Flexible Thin Film Pressure Force Sensing Resistance Sensor Matrix Array 32x64 2048 Point Pressure Distribution Monitoring Pressure Sensing Sheet

Product name:Matrix Array FSR Pressure Sensor

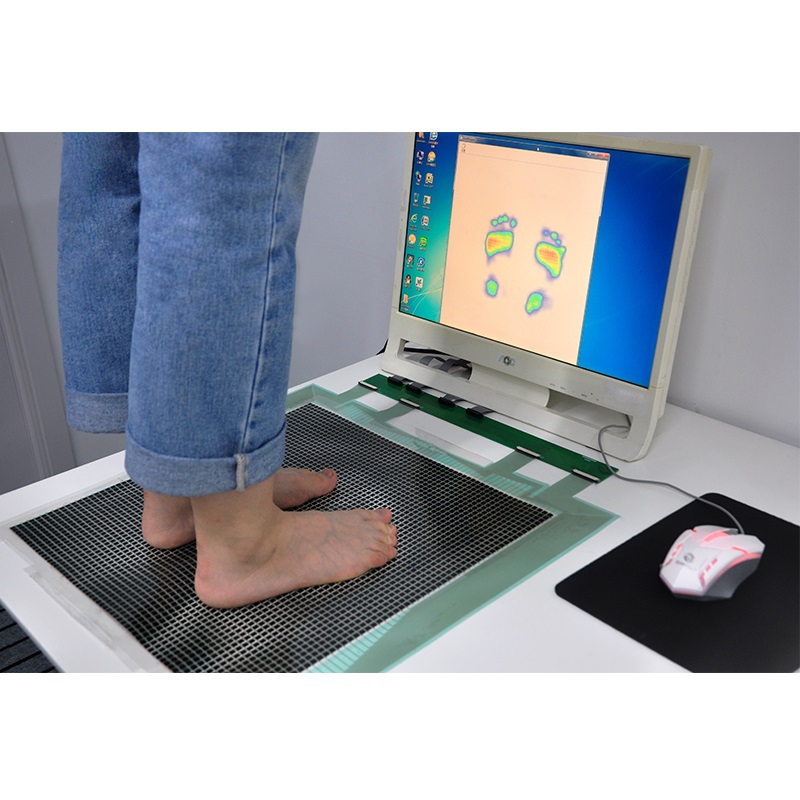

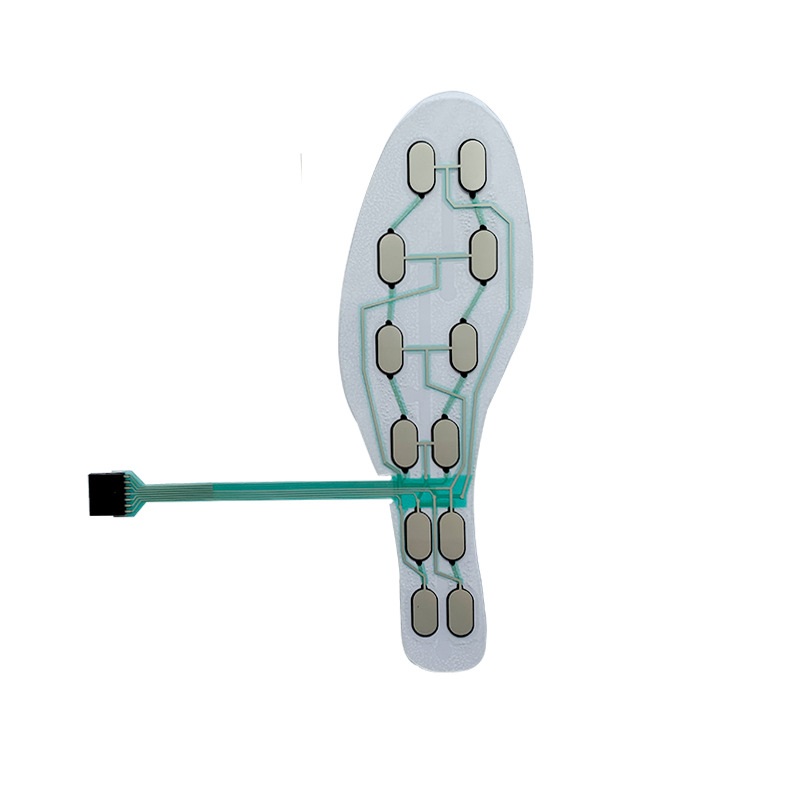

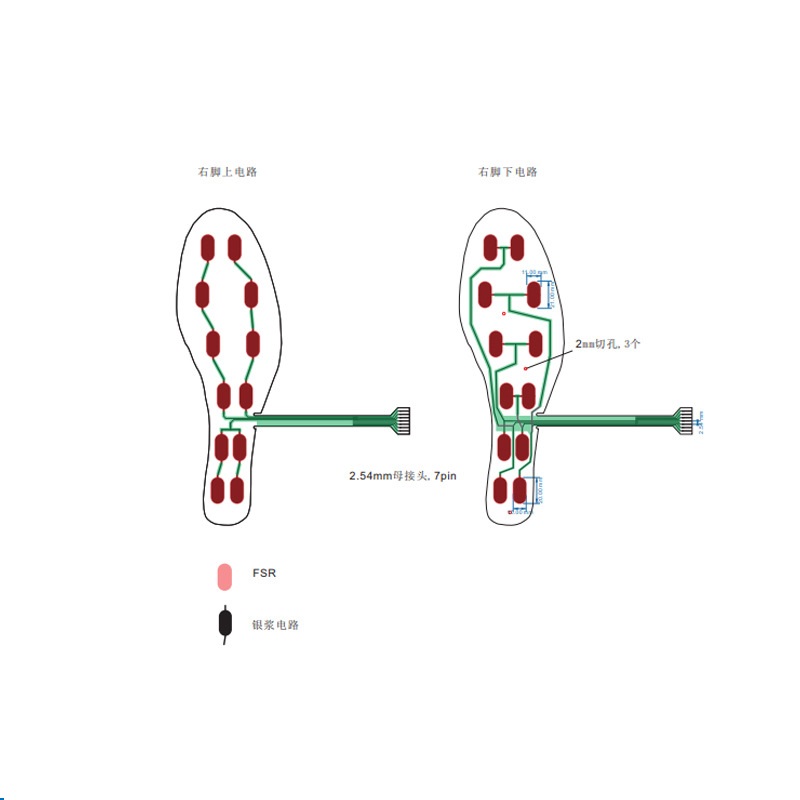

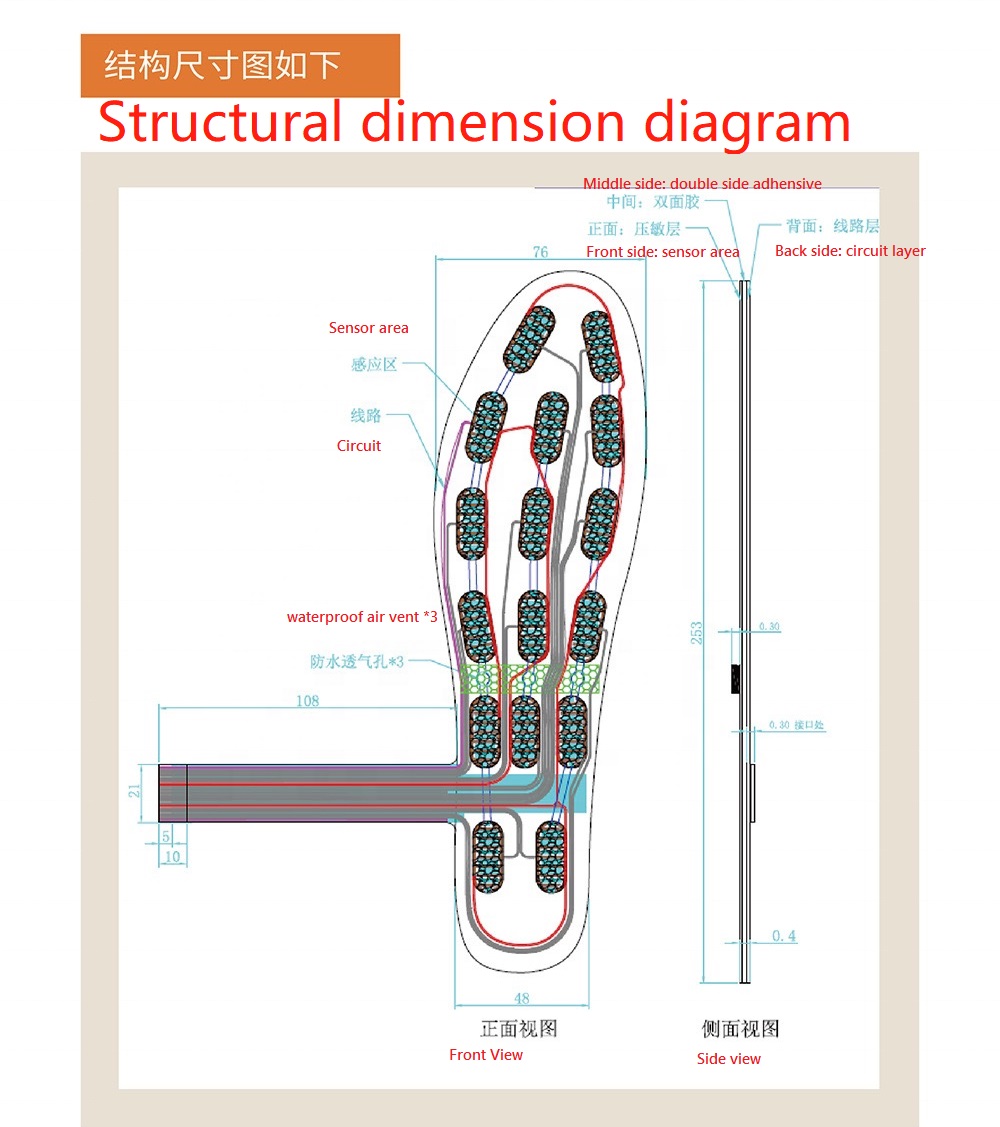

Model Number: FSR Foot Gait Analysis Pressure Sensor

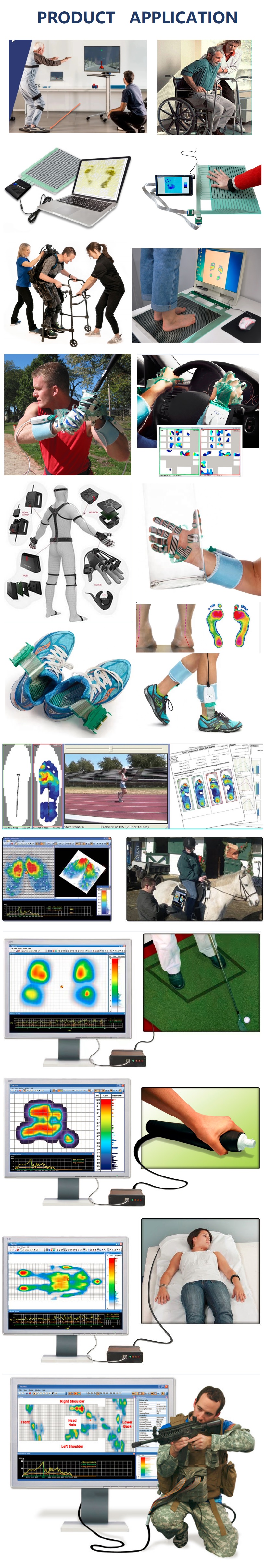

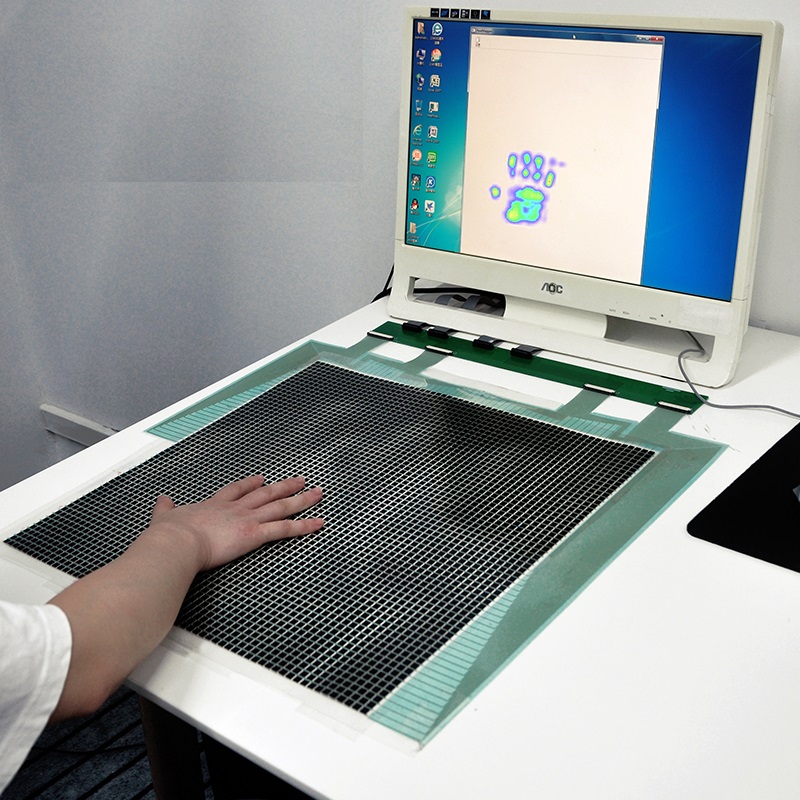

Application:Dynamic Force DIstribution Measurement

Force Range: 3g-300kg

FSR Characteristics: Force Vs Resistance Curve

Working voltage: 3.3V-5V

Response time:2MΩ

Connector:Male/ Female 2.54 pitch /ZIF 1.0mm,2.54mm

Material:PET, FORCE-SENSITIVE INK, SILVER CONDUCTIVE, High Resistance Carbon Film, 3M adhensive,

Certificate:CE, ROHS, FCC, ISO 9001, ISO1400

Video Display

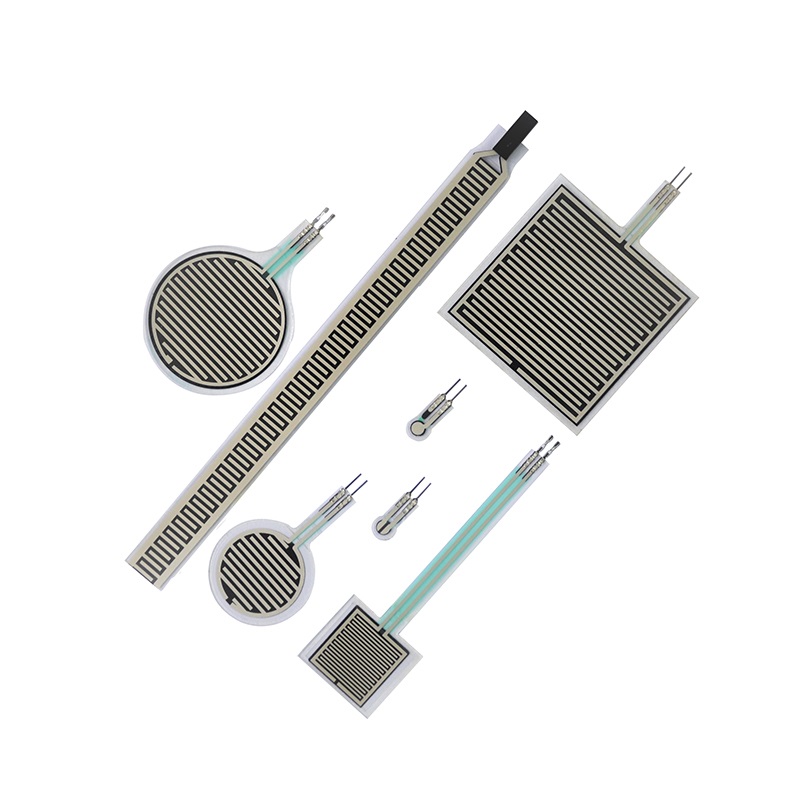

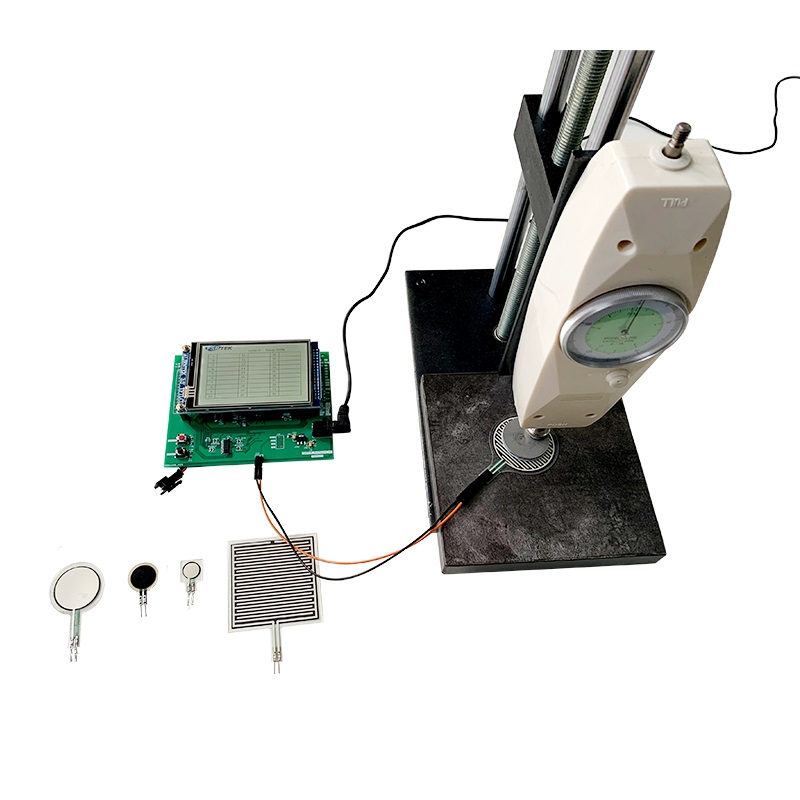

Best In Class Force Sensing Resistors

We make a range of standard force sensing resistors with unparalleled repeatability, hysterisis and thermal performance. Our sensors enable you to perform rapid prototyping and design verification. Our engineering team can provide detailed integration advice and create a custom sensing solution to match your requirements.

Force Sensing Resistors (FSRs) are a cost-effective technology for detecting applied force in a wide range of application areas. Small, light and highly customizable, a Force Sensing Resistor could be the perfect HMI solution in your next product!

Standard Force Sensing Resistors

Wesbay FSR series are best-in-class series' of high-performance Force Sensing Resistors available in industry standard footprints and interconnect options. This extensive range includes both Shunt-Mode and Thru-Mode single-point solutions.

Westbay's force sensors banish the undesirable characteristics found in legacy competing products. We achieve this through state-of-the-art FSR inks, carefully selected materials, intelligent mechanical design, and tightly controlled printing and curing.

Our FSR sensors offer excellent environmental stability, part-to-part repeatability and long-term durability, while maintaining a wide dynamic range, low drift and reassuringly low activation force. Better still, our 10+ years manufacturing experience guarantees high yield, high quality, and very attractive pricing. All devices are RoHS compliant.

For large volume orders we offer customization options for all types, please contact us for more information and mass production pricing.

Sensing Force and Position

Force sensing resistors can be built with varying degrees of functionality to match your requirements. Adding sensing lines and altering the corresponding electronics can allow you to not only sense changes in force, but also changes in position.

A single point sensor is the most basic form of force sensing resistor, only sensing a change in force. Next up, force sensing potentiometers not only sense a change in force but also a change in position in one direction. Force sensing potentiometers can be made in linear or ring configurations.

Force sensing trackpads (aka 4-wire sensors) sense a change in force as well as 2D position, similar to a laptop trackpad but with the added advantage of variable force sensing.

Finally, 3D matrix sensors sense a change in force and will also report 2D position for multiple simultaneous inputs.

The largest part of our business is the design and mass production of semi and fully-custom force sensors for our global client base.

Developing a custom resistive force sensor with Westbay starts with a discovery phase where our engineers will discuss the desired user experience and your mechanical and electrical requirements.

We provide expert advice not only on the sensor design but also on the sensor integration into your product, to ensure consistent and repeatable results.

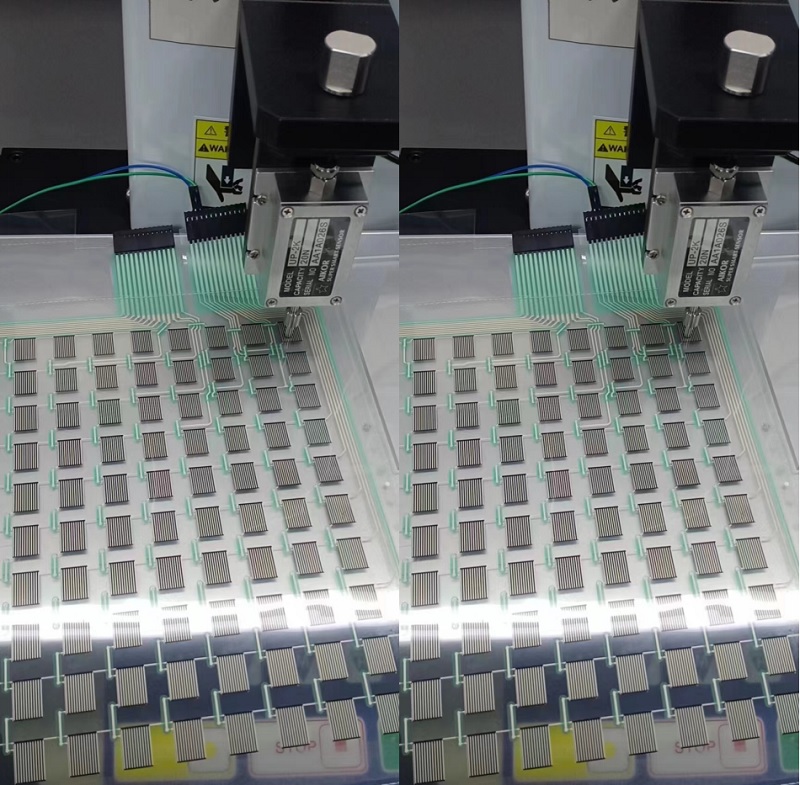

Westbay has full turn-key in-house production facilities for rapid prototyping and high quality production line for mass production.

Time to prototypes is typically only one week, and costs compare very favourably with other technologies.

Custom Design Force Sensing Resistors

The largest part of our business is the design and mass production of semi and fully-custom force sensors for our global client base.

Developing a custom resistive force sensor with Westbay starts with a discovery phase where our engineers will discuss the desired user experience and your mechanical and electrical requirements.

We provide expert advice not only on the sensor design but also on the sensor integration into your product, to ensure consistent and repeatable results.

Westbay has full turn-key in-house production facilities for rapid prototyping and high quality production line for mass production.

Time to prototypes is typically only one week, and costs compare very favourably with other technologies.

How FSR Work?

Shunt Mode

Shunt Mode force sensors are the most frequently used design. They are constructed in two layers of flexible polymer. One layer is printed with Westbay's best-in-class force-sensing ink and the other with printed silver interdigitated electrodes. The two substrates are then positioned facing each other and assembled using an adhesive gasket around the perimeter.

Electrodes can be designed in various configurations depending on the application including, but not limited to: various patterns to influence sensitivity, various materials including silver, copper, carbon and blends, or on a printed circuit board (PCB).

When a force is applied to the device, the shunt or shorting circuit is complete. The more force applied, the more conductive the output.

Thru Mode

Thru Mode force-sensing resistors are constructed in two layers of flexible polymer. Conductive pads, which can be silver, or a silver/ graphite blend ink, are printed on each of the two substrates.

Force-sensing ink is printed on both conductive pads. The two substrates are then positioned facing each other and assembled using an adhesive gasket around the perimeter.

When force is applied, the conductive pads make contact. The more force applied to the Thru Mode device, the more conductive the output.

FSR Characteristics

A typical Force vs. Resistance response (FR curve) is logarithmic and has three principal elements.

1. Break force - This is the force required for the two membrane layers to contact. In this region the resistance is infinite until enough force is applied to make contact.

2. Area Effect - In this region the size of the contact area between the two layers is increasing with increasing force and thereby reducing the resistance.

3. Surface Effect - In this region as the force is increased the contact of the two ink surfaces increases at a microscopic level.

Product Description

Custom Matrix Array Force Sensing Resistor

♦ What is Force Sensing Resistor (FSR)?

Even though there are various types of force sensors, the force sensing resistors are having several advantages such as thin size (less than 0.5mm), very low cost and also good shock resistance. The only disadvantage of FSR sensors is low precision, there will be approximately 10% or more difference in measurement results. So it can’t be used as weighing equipment. It acts as a reaction of force rather than as an accurate reading of pressure.

There are numerous applications for force sensing resistors in various fields such as Foot Gait Analysis, medical bed monitoring, intelligent mattresses, sitting posture monitoring, occupancy analysis, yoga mats, and motion analysis, Medical device, Sports Shoes, Robots hand force, Electronic drum, Boxing strength, Balance scooter, golf sports and so on. It may be used wherever pressure measurements and data collection are required.

|

Force Sensing Resistor Datasheet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FSR Characteristics:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Response time |

1 ms

|

| Resilience time | <15 ms |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PET, FORCE-SENSITIVE INK, SILVER CONDUCTIVE, High Resistance Carbon Film, 3M adhensive

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Certificate: | CE, ROHS, FCC, ISO 9001, ISO14001, IATF 16949 |